Are you new to mass timber or tall wood buildings? If so, this is the best place to start. Tall wood buildings generally refer to any building built from timber that is more than six storeys tall. In Canada, post-and-beam timber buildings up to 8- and 10-storeys were built up until 1941. The introduction of the building code and the prevalence of steel and concrete construction caused people to stop building these large buildings with wood. From that point on, wood buildings, primarily stick frame construction using conventional 2x lumber, were commonplace for buildings up to 3- and 4-storeys in height. Then, in 2009, developers and builders in British Columbia started building up to 6-storeys in height using conventional lumber. By 2015, just 74 years after the introduction of the first building code, the National Building Code of Canada added provisions to allow wood construction up to 6-storeys across the country. Visit our other website, 6wood.ca to learn more about mid-rise wood buildings.

Up to six storeys, conventional wood framing works quite well for residential and commercial mixed use buildings, and fills a void in the mid-rise real estate market for higher density, livable neighbourhoods.

As we see from the existing buildings from about 100 years ago, wood buildings taller than 6-storeys have a proven track record in cities across Canada. These buildings are in high demand in some communities for residential and office space because of the exposed timber, typically in combination with exposed brick. This trend is true in markets in the United States as well, and with growing demand, a new supply of modern tall wood buildings is starting to be built. These buildings tend to be in the 8- to 14-storey range, but there are completed buildings in the 18-storey range with taller ones currently in the planning process.

Why tall wood? What are the advantages of mass timber?

It’s the right time to build tall wood buildings

Modern tall wood buildings are the result of the convergence of 3 things:

- Environmental pressure to use sustainable building materials

- Tight tolerance, high-quality, low site-impact construction

- Prefabricated, short duration construction cycles

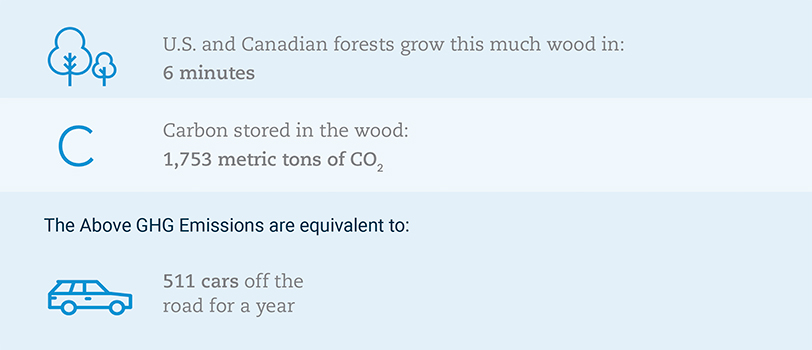

Sustainably harvested timber is a renewable resource that requires very low energy inputs to produce compared to other materials. When trees grow, they remove carbon from the atmosphere and store it in wood. Sequestered carbon (carbon stored in timber) remains part of the building structure helping to offset carbon emissions from other sources.

Estimated Environmental Impact of Wood Use in Brock Commons Building

Read more about The Carbon Economy and Construction.

Read more about The Carbon Economy and Construction.

Automation in sawmill processing and fabrication of mass timber products, such as glued-laminated lumber (glulam), and cross-laminated timber (CLT), has resulted in a very lean, efficient wood processing industry. Automation in fabrication means nearly finished products being delivered to construction sites cut and drilled with high accuracy. This results to less work required on site with minimal site waste, reduced site noise and much faster rates of installation.

Left: Wayne Gretzky Sports Centre, the first commercial installation of CLT (cross-laminated timber) in Ontario. Right: Brock Commons 18-storey mass timber hybrid building in Vancouver, British Columbia.

Left: Wayne Gretzky Sports Centre, the first commercial installation of CLT (cross-laminated timber) in Ontario. Right: Brock Commons 18-storey mass timber hybrid building in Vancouver, British Columbia.

Using sequencing logistics, prefabricated components are delivered to site just-in-time and lifted into place. For example, one 8-storey building in Austria was installed at 1 storey per day, and another 18-storey building in Vancouver was installed at almost two floors per week – this includes the exterior, cladded walls.