It takes a village to raise a child, and it takes many skilled professionals to create a building. Constructing a building takes a large team of people through every phase from land acquisition, design, approvals, construction and final occupancy by owners and tenants. A building is like a factory, employing many people to produce the end product. We have identified 10 key groups who are taking notice of tall wood buildings as potential areas for growth in their professions.

- Developers

- Real estate brokers

- Architects and structural engineers

- Planners

- Building Officials

- Fire Officials

- General contractors and construction managers

- Building trades

- Manufacturers of mass timber

- Foresters

Land developers are the ones willing to put money on the line when they see an opportunity. Tall wood buildings have great potential for residential and office buildings. But developers need the tools to understand the cost and schedule of building with mass timber. They can get these key pieces of information for their pro formas by engaging with the design team and suppliers early on with design assistance.

Once complete, tall wood buildings perform the same way as any other building. However, the way they are delivered is much different than conventional construction. Purchasers and leasers may get the benefit of exposed wood elements in their suites. Positive health attributes have been documented for occupants of spaces with exposed wood. In fact, these buildings tend to rent and sell faster than conventional buildings.

Architects and structural engineers have been at the leading edge of the change to mass timber construction. But like any new system, there is still much to learn. Other consultants who specialize in mechanical engineering, electrical engineering, acoustics, code, and building science have to learn new ways of approaching these buildings.

You’ll want to put together an experienced team with the technical resources for your mass timber building. We can help you with your decisions for mass timber buildings related to strength, availability, performance and scheduling.

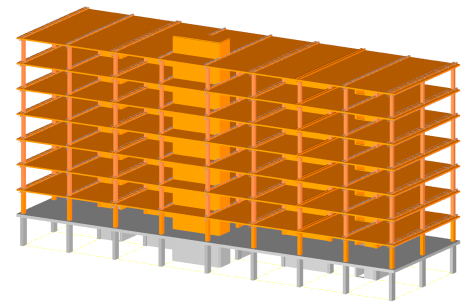

City planners want more density in cities without compromising on liveability. Most tall wood buildings are targeted to the mid-rise market between 8- and 14-storeys. The properties of mass timber are perfectly matched for the needs of intensification with the added benefit of faster construction cycles, quieter job sites and less disruption to neighbourhoods.

Building Officials who provide approvals at the municipal level for building permits ensure that the objective and performance requirements of our building codes are being met. Since tall wood buildings are new to the industry, building officials rely on the most current best practices to assist them in their approvals.

Moses Structural Engineers is co-author to Ontario’s Tall Wood Building Reference specifically written for building officials to understand the concept of mass timber, the questions to ask the design teams, and a pathway for approval even within building codes that do not currently address mass timber and tall wood buildings.

Tall wood buildings are built from mass timber and are designed to perform differently than other materials including conventional stick frame wood construction. Specialized fire simulations and full-scale tests have provided answers for fire officials about fire behaviour in these structures. Ontario’s Tall Wood Reference has detailed information for fire officials who are assessing tall wood buildings during the application process.

Builders are taking note of tall wood buildings because they offer a new way of delivering a project. Prefabrication and sequencing simulation are great reasons to consider mass timber. During prefabrication, the building components are checked in 3D models to confirm geometry, cuts and holes, connections and assemblies. Precision manufacturing reduces site installation time and improves quality of construction. Computer simulations of the site installation process allow the construction team to predict interferences between deliveries, sharing of crane resources and time interactions between trades. Since more of the construction takes place in a shop, site crews can be smaller and the type of work on site tends to be quieter.

Tall wood building teams require a lot of players, especially the trades. Qualified carpenters and installers are critical to maintain the safe and efficient installation of these new systems. The proactive colleges are seeing the opportunity for training the trades in this industry, so they can keep up with the latest advances in mass timber building systems.

Tall wood buildings use mass timber. The primary sawmill industry has become more advanced and automated to use our renewable resources more efficiently. Similarly, the secondary industry, i.e. processing and manufacturing in the forest sector, has advanced significantly in North America since 2000. The mass timber industry uses 3D modelling and CNC machining which has changed the way we build with wood to a factory automation approach. Precision-machining, a term normally used for the automotive and watch-making industries, is now the norm in mass timber and is paving the way for the new generation of tall wood buildings.

This is an exciting time to be working in the forest sector. As a renewable resource, sustainably-harvested forests are a critical component of tall wood building. The environmental benefits of carbon sequestration in tall wood buildings is tied closely to the ability of foresters to map and manage forest resources. Technology is advancing at a rapid pace in this sector too, including 3D biomass mapping using drones.

Who else is building tall wood and mass timber buildings? Click here to learn more.